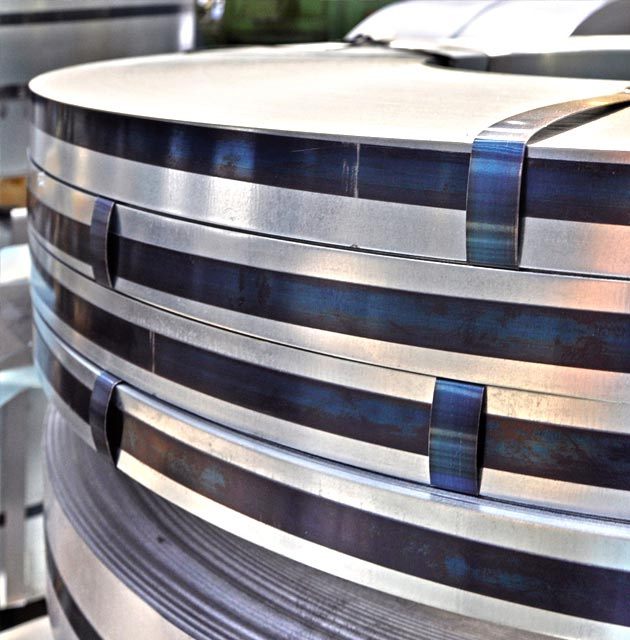

Production lines

In order to provide end user with excellent and constant quality over time, we realize an ongoing modernization of plants, in such a way that we can always have the most advanced production lines capable of being able to generate a maximum annual production capacity of 200,000.

At present Marcora SpA in Cuggiono (MI), has 3 lines with processing capacity of maximum thickness of 6 mm and maximum width 2000 mm.

The industrial activity of Marcora SpA is carried out on a surface area of 24,000 square meters of which 13,000 square meters are covered.

The different buildings that constitute the production system, or are newly built or completely modernized in accordance with the latest provisions laws

and are absolutely free of asbestos cement roofing.

The internal handling equipments are executed with an interior rail transport systems in electric locomotion and 8 cranes maximum flow rate up to 35 tons.

Logistic

Marcora supplies its customers throughout Europe every day with punctuality, efficiency and accuracy through an extremely functional logistics service. The rapid delivery

service is the flagship of the company’s organization, ensuring maximum distribution punctuality.

The company has 2 warehouses (coils, sheets and finished products) where goods are stored in readiness for scheduled orders.

A small fleet of owned trucks dedicated to the transport of steel flat products in coils, strips or sheets, wants to ensure timely service delivery to the customer in every case.